And finally… House built on solid grounds

A company in Columbia has found a novel use for the husks discarded when coffee is roasted by turning them into building materials.

Bogota-based Woodpecker combines the papery natural material around coffee beans with recycled plastic to create a new lightweight, strong material to make the walls of its prefab houses, which cost as little as $4,500.

Normally the husks become waste, dumped in piles that release methane, a potent greenhouse gas.

The company started developing the solution a decade ago.

“We saw that there was a huge necessity for a lightweight construction system for housing and classrooms in rural and isolated places where traditional construction systems cannot go—like bricks, cement, and concrete,” CEO Alejandro Franco told Fast Company. The startup needed to find materials light enough to move in a small boat, a helicopter, or on the back of a burro. It tested combining different natural fibers, from sawdust and rice to grass and palm fiber, with different types of recycled plastic.

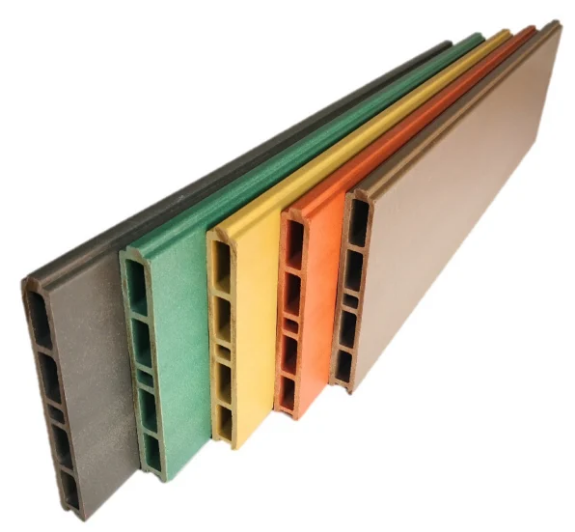

The house that coffee built (Image courtesy of Woodpecker WPC)

“Coffee husk was selected because it’s stronger and drier than the other fibres,” he added.

It’s also widely available in Colombia, one of the largest coffee-producing countries in the world. The final material is fireproof, durable, and resists insects.

The company makes Lego-like kits that can easily be assembled on-site, with a steel frame and coffee husk boards that click together easily with minimal tools. (While the company builds most homes itself, some customers buy the kits and put them together themselves.) By designing each model of home to use as few parts as possible, and standard parts between different designs, the team helped keep costs low. The recycled material is also affordable, and Woodpecker lowers costs further by producing materials at a large scale.

Image courtesy of Woodpecker WPC

Construction typically takes less than a week. Last November, when the Category 5 hurricane Iota hit the Colombian island of Providence, destroying 1,300 homes, the Colombian government asked Woodpecker to help.

“They needed a fast solution and a lightweight construction system,” said Franco. The company donated two houses, which the army helped build in five days. “We shipped a complete kit from our factory,” he said. “The system worked perfectly considering that there was no energy supply, the soil was muddy, the airport damaged, no food, etcetera—all the problems that you can imagine.”

As the company continues to build housing in other low-income areas, it also hopes to get orders and government approval to help rebuild the island at a larger scale.

“We think our houses are an excellent solution for the housing crisis there,” Franco said. “It has been proven already.”